What and Why We Do

To stay competitive in today’s marketplace, manufacturers must maintain flexibility in their production systems because products have shorter life cycles and consumers are demanding a greater variety of goods, high-volume and rigid automated production lines are not desirable. Manual labors are still the primary workforce in the factories across many industries, due to humans’ versatility and autonomy. Adoption of robots is limited. Intelligent and autonomous robots could increase autonomy and agility to enable manufacturers to respond efficiently to the rapid changes of customers’ needs and desires, have the potential to expand beyond automotive industry.

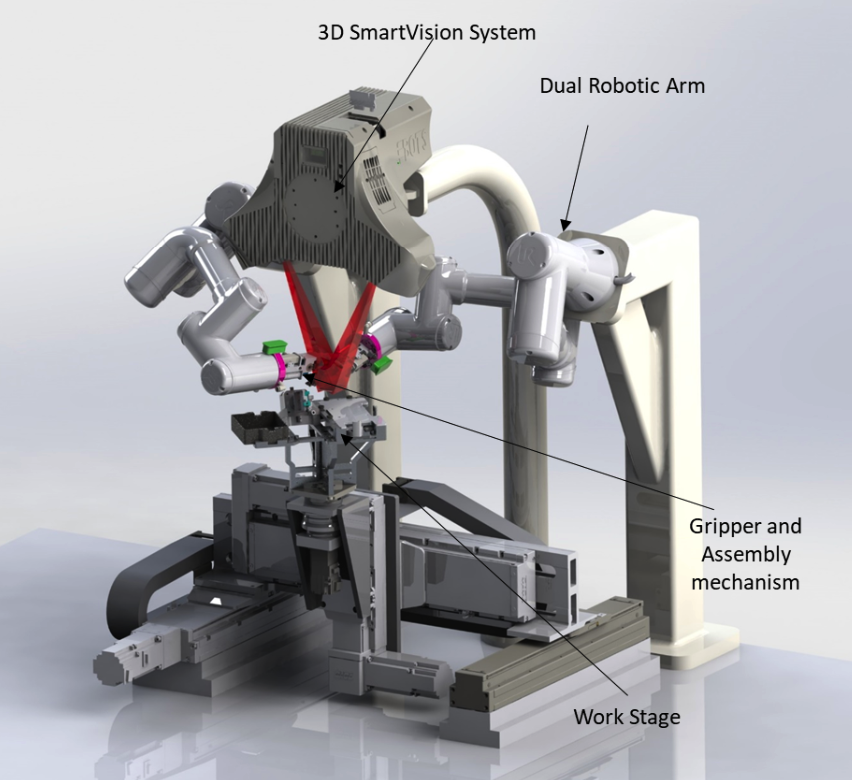

We developed a SmartVision guided autonomous robotic system that can perform various light-load assembly tasks in semi-structured and unstructured environments with minimum human intervention. The robot is flexible, reconfigurable, and adaptive to the rapid change of product demand. Our proprietary technology consists of the best of deep learning algorithms and physical models, so that effective eye-to-hand coordination can be achieved. The hardware portion of system comprises two high-speed laser structured light projection modules, four high-speed image acquisition modules, dual robotic arms, dexterous precision end-effectors. The software portion comprises the algorithms to determine and track six object’s degrees of freedom (6DOF) in real time; the algorithms to synchronize the motion of dual arms, and the algorithms for real-time path and motion planning.

The robotic system consists of high-speed 3D computer vision module, dual robotic arms, grippers and assembly mechanism, and work stage, as shown in Figure 2. By lining up these robots along a convey belt, a versatile and adaptive automation line is formed, as shown in Figure 3.

The robot can perform various assembly tasks in electronics industry, e.g., smartphones, tablets, laptops, PCs, and electronic instruments and equipment.